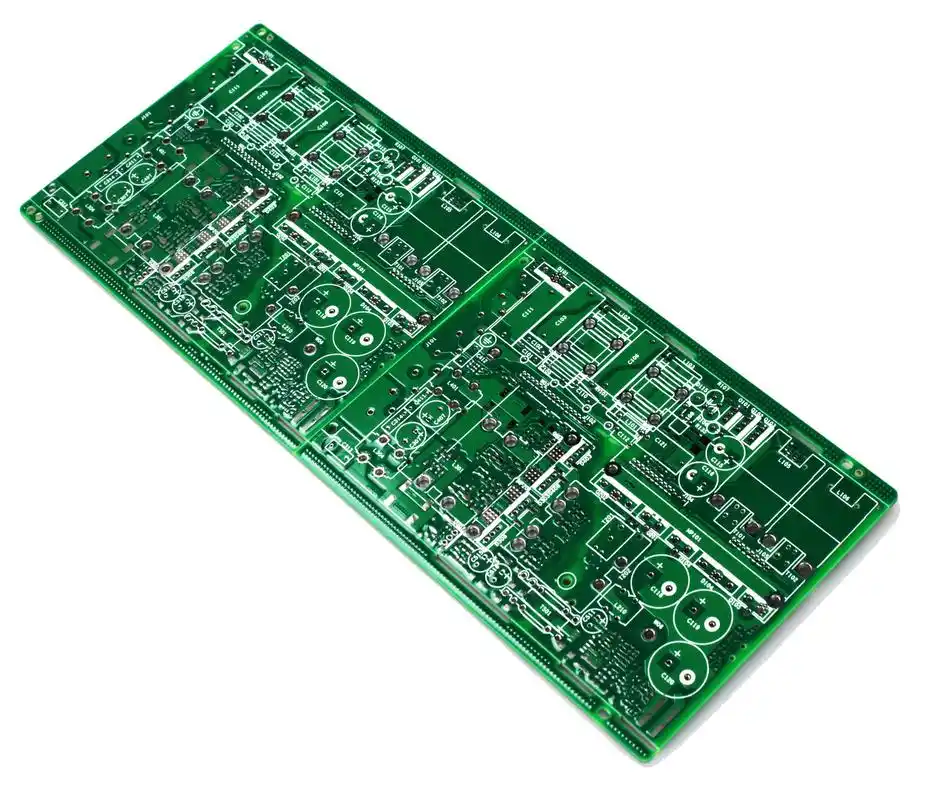

Our company’s low-density glass fiber materials include densities such as 0.8, 1.0, 1.2, and 1.4. They are mainly used for flat panel protective cases and flat panel battery covers. We have already participated in several projects for HUA WEI, SAMSUNG, and HONOR tablets and their protective cases.

The use fiberglass board of low-density (density 0.8g/cm3), with high strength, low density, instead of glass and eliminate aluminum alloy frame, weight reduction of more than 70%, reduce the border ash, can be directly attached to the roof installation, greatly reduce the installation cost, can be widely used in the future rural roof.

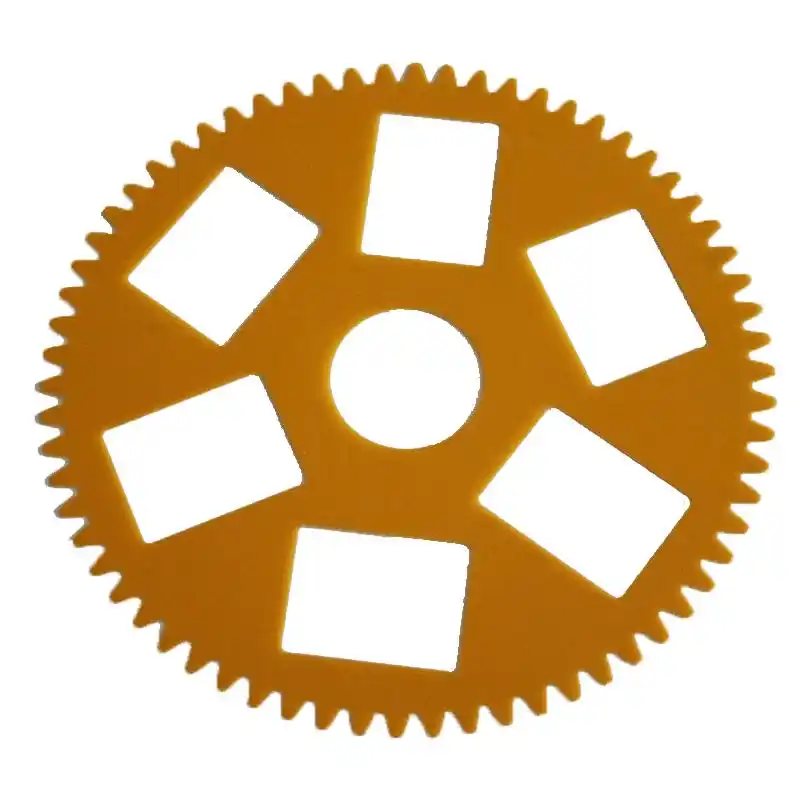

The wear-resistant star wheel

The wear-resistant star wheel used in glass, lens, silicon, hard disk and other flat polishing process fixture, also known as polishing fixture, polishing pad, etc; Polishing process development for many years, has been very mature, in recent years, mobile phones, tablet computers and other popular electronic products, touch screen rapid development, lens polishing development of a thousand miles a day, the raw material of the star wheel from the original blue steel sheet into FR-4 glass fiber board.

The wear-resistant star wheel is upgraded on the basis of the ordinary FR-4 glass fiber board star wheel, and the wear-resistant degree is increased by 2 to 3 times compared with the ordinary FR4 glass fiber board star wheel, greatly reducing the cost of consumables.

New Energy Vehicle Heating

Conventional power battery epoxy heating plate with fire grade up to UL-94V0, high strength, uniform heating, good insulation, Life Durable shape can be customized and other features.

The epoxy heating plate developed by our company has the above characteristics, there are heating core on both sides, one side of high thermal conductivity, more than 2W / (m-K), one side low thermal conductivity, thermal conductivity 0.2W / (m.K) below, effective reason heat source, reduce heat loss, and has the function of heat insulation.

Used Prepreg (carbon fiber, basalt fiber, etc.)to 3D hot bending process for instead of 6061 with aluminum alloy material for new energy vehicle chassis three electric armor, weight reduced by 40%, strength increased by 85% VS aluminum alloy material, effectively improve the battery range, better protect the chassis 3 electricity.

Our company’s low-density glass fiber materials include densities such as 0.8, 1.0, 1.2, and 1.4. They are mainly used for flat panel protective cases and flat panel battery covers. We have already participated in several projects for HUA WEI, SAMSUNG, and HONOR tablets and their protective cases.