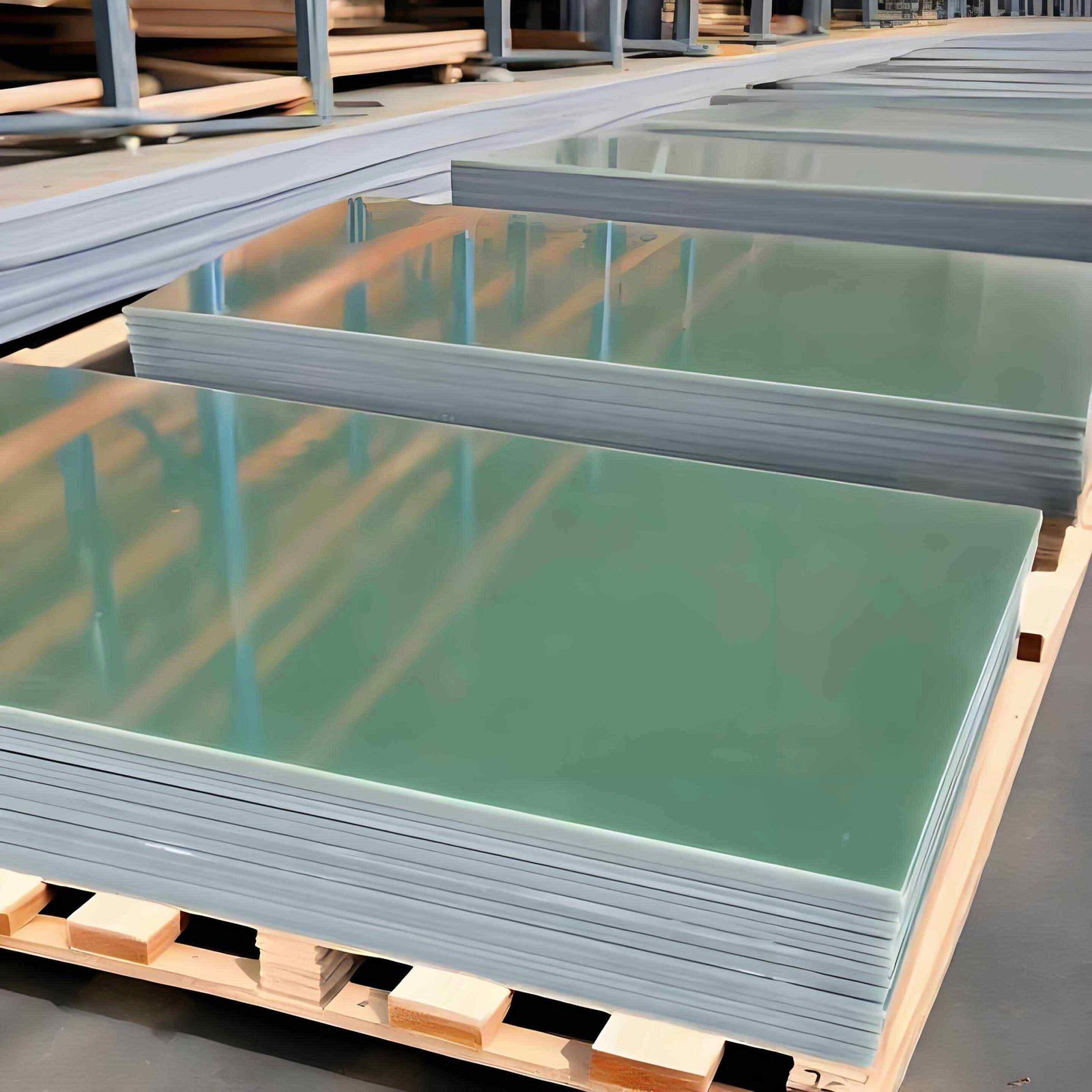

Epoxy boards are commonly used in modern interior design, but are they heat-resistant? As the use of epoxy boards becomes more and more widespread, curiosity about their characteristics has grown. To better understand epoxy boards, let’s explore their key features.

Is Epoxy Board Heat-Resistant?

- Prevents Hazards of Layering and Deformation

Under high temperatures, the surface of epoxy boards may warp, discolor, or even exhibit uneven textures. Fortunately, their heat-resistant properties help avoid such issues. - Protects Functional Integrity

High temperatures not only affect the board’s appearance but can also compromise its performance. Heat resistance safeguards its core functionality. - Extends Service Life

By mitigating damage from adverse conditions, heat resistance delays aging, reduces replacement frequency, and enhances production efficiency.

What Are the Key Features of Epoxy Boards?

- Familiar Insulation Material

Widely recognized for their excellent insulation, mechanical processing performance, and heat resistance, epoxy boards may be less understood in terms of production processes. - Robust Mechanical Properties

Stable performance under diverse conditions (e.g., varying materials, temperatures, and humidity) allows them to withstand loads such as tension, vibration, impact, and bending. - High Adaptability

Suitable for a wide range of applications, from low-viscosity solutions to high-melting-point solids. - Broad Curing Temperature Range

Curing can occur within 0–180°C, offering flexibility in manufacturing. - Low Shrinkage Rate

Minimal release of water or volatile chemicals during production. Curing shrinkage is typically below 2%, ensuring dimensional stability. - Exceptional Adhesion

Polar hydroxyl and ether groups in its molecular structure enhance adhesion, while low internal stress ensures strong natural bonding. - High Heat Resistance

Withstand temperatures up to approximately 160°C, making them ideal for demanding applications in electronics and appliances.

Is Epoxy Board Heat-Resistant?

Epoxy boards are commonly used in modern interior design, but are they heat-resistant? As the use of epoxy boards becomes more widespread, curiosity about their characteristics has grown. To better understand epoxy boards, let’s explore their key features.

Is Epoxy Board Heat-Resistant?

- Prevents Hazards of Layering and Deformation

Under high temperatures, the surface of epoxy boards may warp, discolor, or even exhibit uneven textures. Fortunately, their heat-resistant properties help avoid such issues. - Protects Functional Integrity

High temperatures not only affect the board’s appearance but can also compromise its performance. Heat resistance safeguards its core functionality. - Extends Service Life

By mitigating damage from adverse conditions, heat resistance delays aging, reduces replacement frequency, and enhances production efficiency.

What Are the Key Features of Epoxy Boards?

- Familiar Insulation Material

Widely recognized for their excellent insulation, mechanical processing performance, and heat resistance, epoxy boards may be less understood in terms of production processes. - Robust Mechanical Properties

Stable performance under diverse conditions (e.g., varying materials, temperatures, and humidity) allows them to withstand loads such as tension, vibration, impact, and bending. - High Adaptability

Suitable for a wide range of applications, from low-viscosity solutions to high-melting-point solids. - Broad Curing Temperature Range

Curing can occur within 0–180°C, offering flexibility in manufacturing. - Low Shrinkage Rate

Minimal release of water or volatile chemicals during production. Curing shrinkage is typically below 2%, ensuring dimensional stability. - Exceptional Adhesion

Polar hydroxyl and ether groups in its molecular structure enhance adhesion, while low internal stress ensures strong natural bonding. - High Heat Resistance

Withstand temperatures up to approximately 160°C, making them ideal for demanding applications in electronics and appliances.

Summary

Epoxy boards are heat-resistant, with many advantageous properties. If they meet your interior design needs, they are a reliable choice. However, always apply them properly. If their properties seem incompatible with your requirements, consider alternative materials.

Why Choose Forest Epoxy Boards?

Forest is a professional epoxy board design and manufacturing company. Our epoxy boards are engineered with advanced heat-resistant capabilities, ensuring reliability even in high-temperature environments.

Six Key Advantages of Choosing Us:

- Custom Solutions – Tailored designs to meet your unique project needs.

- Superior Heat Resistance – Built to withstand temperatures up to 160°C.

- Precision Manufacturing – Quality-controlled production for consistency and durability.

- Eco-Friendly Practices – Sustainable materials and processes prioritized.

- Fast Turnaround – Efficient production and delivery to keep your projects on schedule.

- Expert Support – Dedicated technical team for seamless collaboration and troubleshooting.

Choose Forest for epoxy boards that combine innovation, performance, and trust. Contact us today to elevate your designs! 🌟